Introduction:

In the fast-paced world of manufacturing, efficiency is key to staying competitive. One powerful tool that can revolutionize operations and boost productivity is the ERPnext Manufacturing Module. By integrating various processes into one cohesive system, this comprehensive software solution simplifies workflows, enhances communication, and provides real-time insights. Let's dive deeper into the benefits of implementing the ERPnext Manufacturing Module in your manufacturing business.

Streamlining Manufacturing Processes for Enhanced Efficiency:

The ERPnext Manufacturing Module offers a wide range of capabilities designed to streamline and improve manufacturing processes. It enables users to access data from multiple sources, empowering informed decision-making. With advanced scheduling and tracking features, materials are used efficiently, reducing waste and optimizing resource utilization. Moreover, the module provides valuable analytics tools that identify trends and anticipate future needs accurately. This ensures that your business is equipped with the right resources at the right time, meeting customer demands while increasing operational efficiency.

Integration for Greater Visibility and Reduced Errors:

Integrating the ERPnext Manufacturing Module with other third-party software solutions, such as warehouse management systems and supply chain management, brings greater visibility to all aspects of your manufacturing operations. This integration eliminates manual data entry, minimizing errors and discrepancies between departments. The result is a cohesive system that enhances communication and coordination, allowing teams to respond swiftly to changes in product specifications or requirements. With reduced manual labor and streamlined workflows, your business gains a competitive edge in the industry.

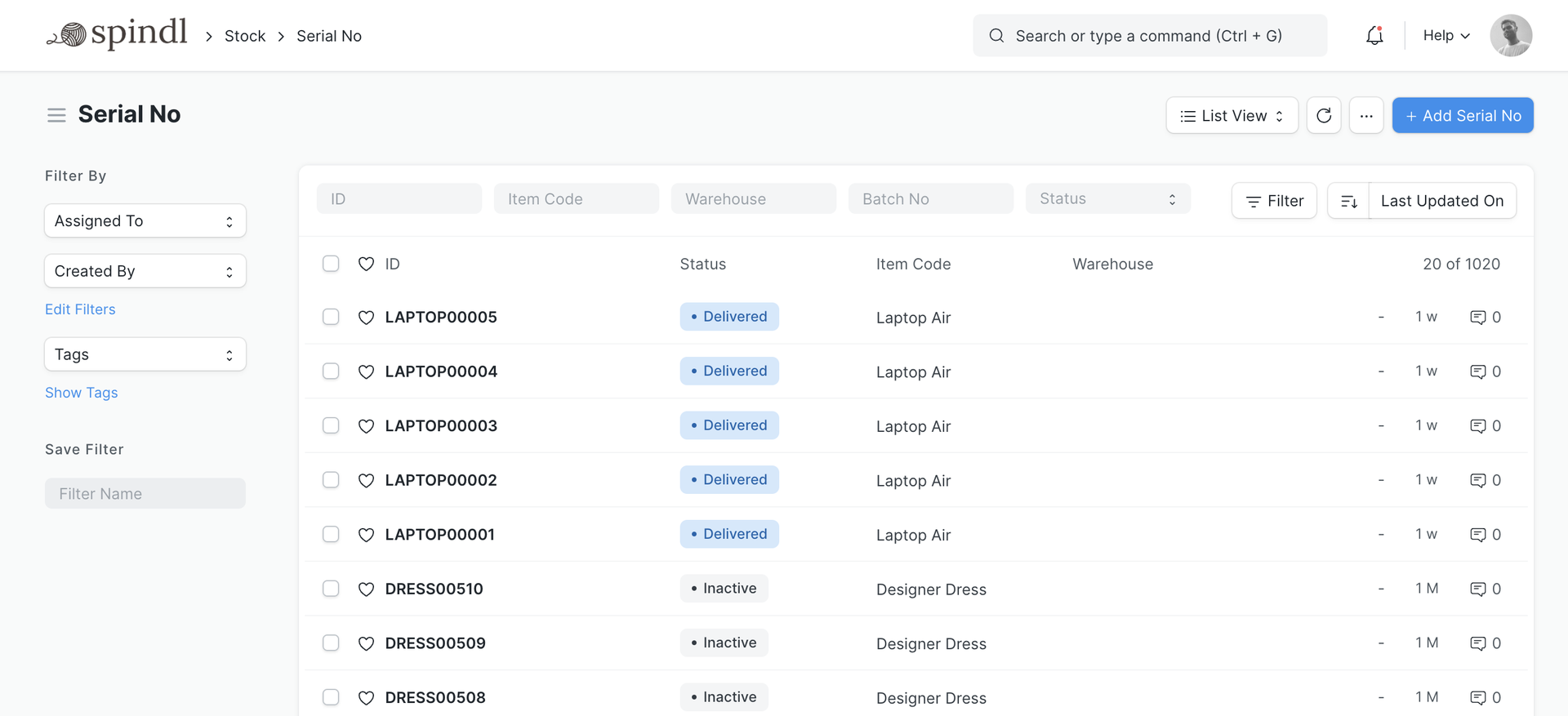

Real-Time Inventory Tracking and Informed Decision-Making:

One of the standout features of the ERPnext Manufacturing Module is its ability to provide real-time inventory tracking. Manufacturers can access up-to-date inventory information instantly, enabling them to make informed decisions when restocking materials for production runs. This eliminates the risk of overstocking or understocking, leading to significant cost savings. By automating scheduling and tracking, the module ensures that resources are utilized efficiently, reducing waste and boosting overall productivity levels.

Strengthening Business Relationships and Customer Satisfaction:

The ERPnext Manufacturing Module goes beyond internal optimization. Its advanced analytics tools enable manufacturers to identify trends in order patterns, anticipate future needs, and align their production accordingly. By meeting customer demands accurately and efficiently, businesses can enhance customer satisfaction and build stronger relationships. Additionally, the module facilitates smoother communication between teams, ensuring rapid responses to changes without the burden of manual data entry into separate systems. This integration fosters collaboration and helps your business maintain a competitive edge in the industry.

Implementing ERPnext Manufacturing Module:

Tips for Success: To make the most of the ERPnext Manufacturing Module, there are a few tips to keep in mind. Understand your current workflows and identify areas where automation can be introduced for maximum efficiency. Custom reports tailored to your specific business needs provide valuable insights for decision-making. Establish clear roles and responsibilities among team members to effectively manage the system. Invest in adequate training sessions to ensure a smooth transition and empower users with hands-on experience. Finally, thorough testing before going live guarantees a seamless integration and minimizes potential issues.

Conclusion:

In today's competitive manufacturing landscape, optimizing operations and increasing efficiency are essential. The ERPnext Manufacturing Module offers a comprehensive solution that streamlines processes, improves productivity, and enhances customer satisfaction. By centralizing data, providing real-time inventory tracking, and integrating with other software solutions, businesses can unlock the full potential of their manufacturing operations. Implementing the ERPnext Manufacturing Module positions your business for success, enabling you to thrive in a dynamic and demanding industry.